Guard / ring / permanent magnet elevator

Product Introduction

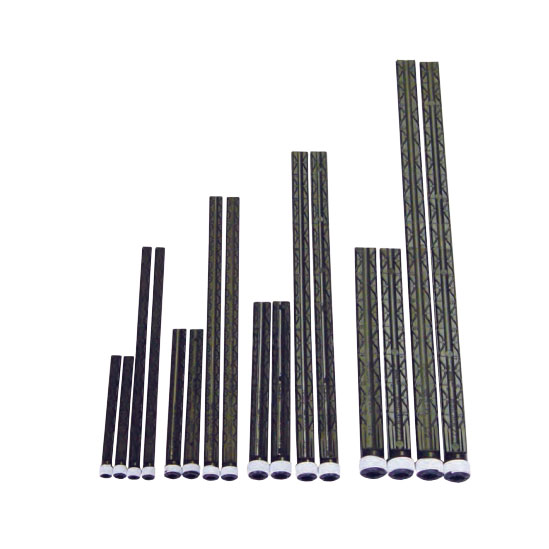

Characteristics of turbulent plastic baffles

• Better cooling of target hot spots.

• Significantly improve cooling time.

• Increase the coolant flow rate and reduce the "T" of the coolant flow rate across the mold surface.

• Built in ribs to encourage turbulent flow and reduce stagnant laminar flow.

• Turbulent dissipation is approximately 3 times that of btu compared to laminar flow.

• Non hygroscopic, glass reinforced engineering thermoplastic (polyaniline).

• Excellent performance at high temperatures, providing better temperature stability.

• Pre packaging with TPFE tape.

• Recommended maximum coolant temperature: 100 ° C (212 ° F).

Features of spiral brass plug baffle

Spiral baffles improve cooling balance by creating turbulence.

Reduce laminar or straight flow patterns and provide effective coolant movement within the channel.

Features of straight brass plug baffles

The function of the baffle is to split the borehole water line.

Enter two equal channels. As a heating or cooling medium.

When entering, the baffle directs the water flow up and above.

One end of the baffle and the other end.

There must be a gap between the two ends of the baffle and provide sufficient flow at the end of the drilled channel.

Refer to dimension "C" for approximate clearance.

Rings

Material: alloy steel (certified heat treated), black oxide.

Safety factor: 5 times the rated load in any direction.

Scope of activity.: 360 ° rotation; 180 ° main.

Permanent magnet elevator

Bunting ® MagLift permanent magnet elevator is powered by high-energy neodymium magnetic blocks. Switching is achieved by inverting one of the blocks. In the "ON" position, the reversible block is parallel to the stationary block, which releases the concentrated magnetic field generated at the pole foot. In the "OFF" position, the reversible block rotates 180 ° to provide a full magnetic short circuit within the elevator body.